CNC Milling & Turning

Elevate Your Manufacturing with Cutting-Edge CNC Solutions

In today’s fast-paced industrial landscape, precision and efficiency are not just advantages – they’re necessities. At Machining Technologies, we’re revolutionizing the way corporate clients approach their manufacturing needs with our state-of-the-art CNC Milling and Turning services.

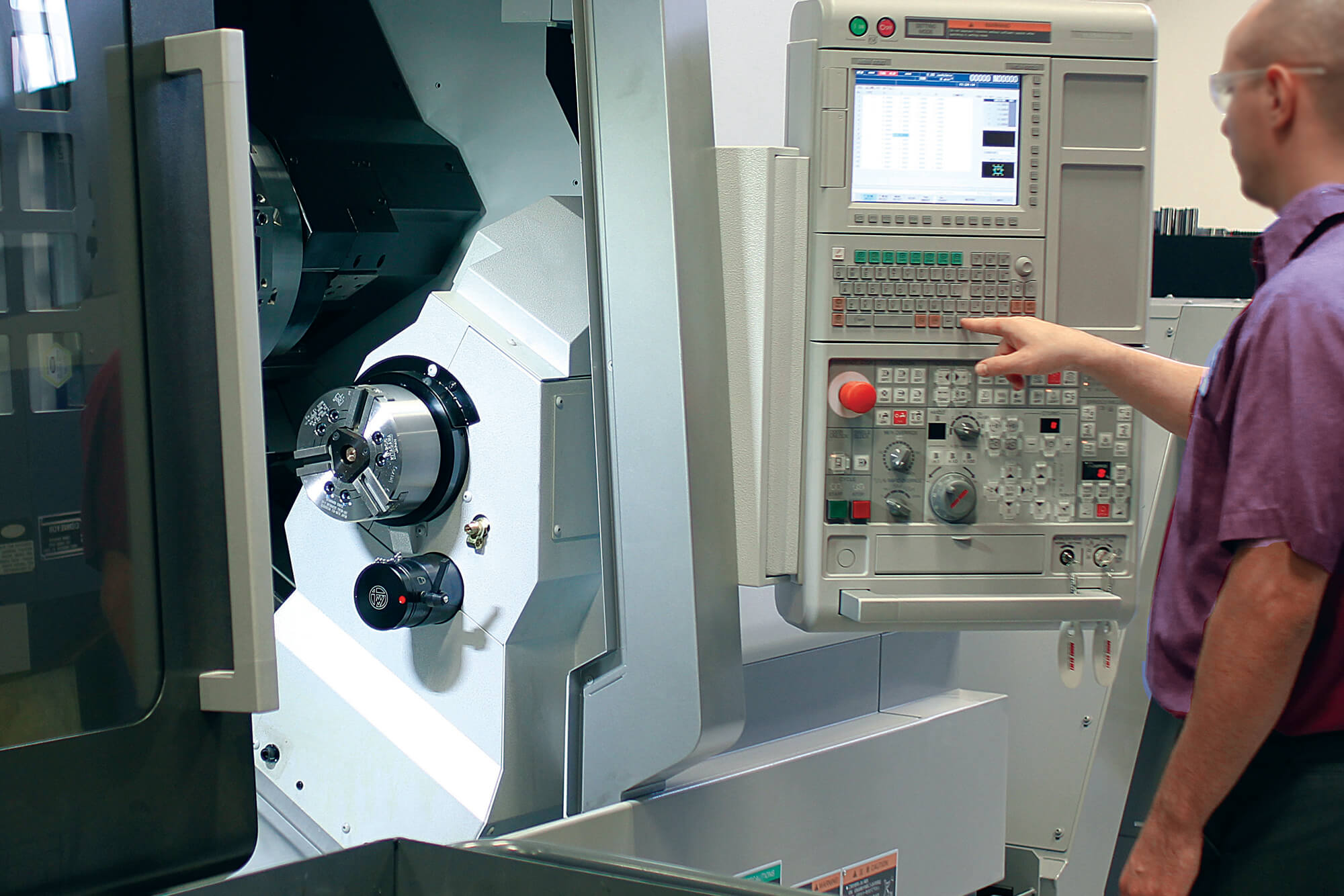

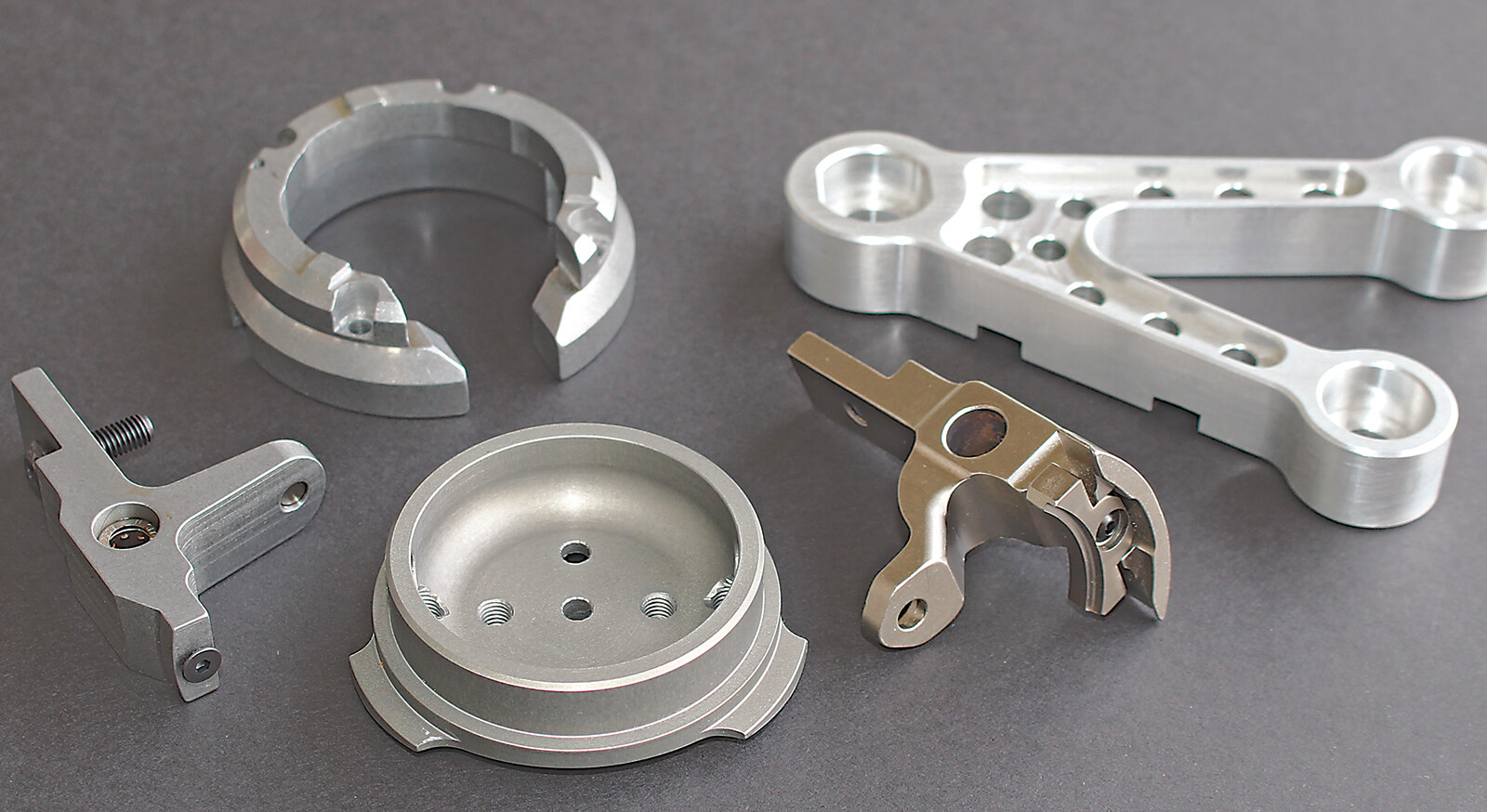

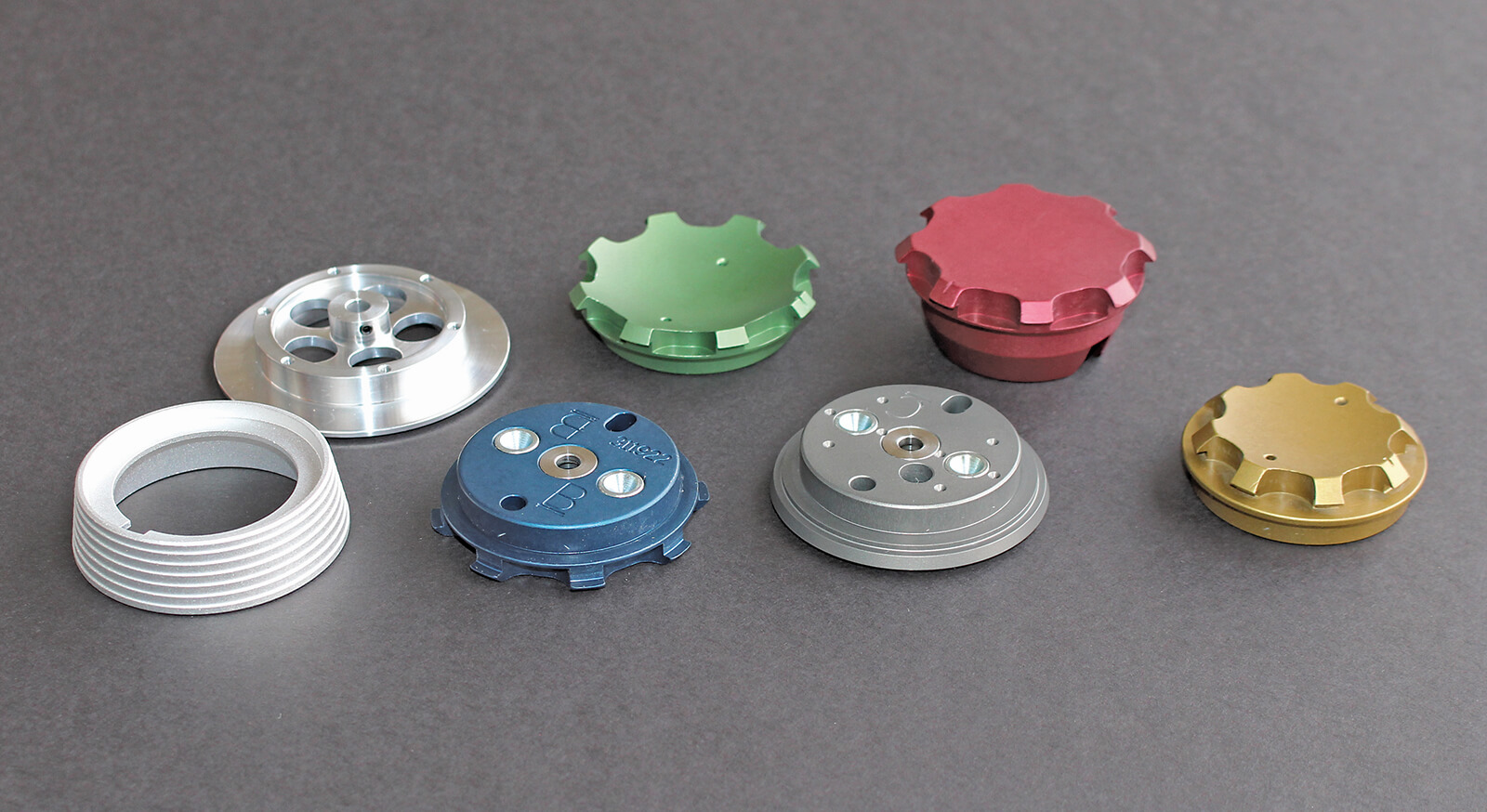

For larger components, Machining Technologies professionals are well equipped with state of the art CNC machines to heighten productivity while significantly reducing cost. Their flexible work holding options handle a broad range of part and order sizes for super quick setups, efficient changeover ensure timely production of your prototypes and low volume runs. Our trained and experienced staff meet your toughest requirements and are experts in high speed metal removal, and are fully equipped and trained to handle multiple orders with precision, maximum throughput, and immediate delivery. We offer expertise in CNC Prototyping in all metals and high performance materials. Computer-aided-manufacturing, regulatory inspection, and other key services, accommodating a wide range of part sizes and quantities.

Versatility Across Industries

Whether you’re in aerospace, automotive, medical devices, or any sector requiring precision components, our CNC Milling and Turning services are tailored to meet your specific needs. We pride ourselves on our ability to adapt to diverse industry requirements, ensuring that your unique challenges are met with innovative solutions.

Why Choose Our CNC Milling and Turning Services?

Heightened Productivity

Our advanced CNC machines operate with lightning speed and unwavering precision, dramatically reducing production times.

Significant Cost Reduction

Efficient processes and minimal waste translate to substantial savings for your bottom line.

Unmatched Flexibility

From prototypes to low-volume runs, our flexible work holding options accommodate a vast range of part and order sizes.

Quick Setups, Faster Turnarounds

Our streamlined processes ensure efficient changeovers, getting your products from concept to reality in record time.

CNC Milling

- Experience milling Hastelloy, Inconel, titanium and other exotic alloys

- High pressure coolant for higher cutting speeds and better chip control

- CAT 40 tool holders and large tool magazines

- Mastercam software for complex tool paths

- 4th axis milling capability

CNC Turning

- Capacity to bar feed up to 3 1/2″ diameter material

- Chuck work up to 24″ diameter material

- Experience machining stainless steel, aluminum, brass, steel, aircraft and high temperature alloys, and plastics

- Large tooling capacity to machine complex parts in a single setup

- Prototype production as well as small and medium quantity production runs available

Ready to Transform Your Manufacturing Process?

Don’t let outdated manufacturing methods hold your business back. Embrace the future of precision engineering with Machining Technologies.

Step into the future of manufacturing with our cutting-edge CNC machines. Our team of skilled professionals harnesses the power of these technological marvels to bring your designs to life with unparalleled accuracy and speed.

CONTACT US