Our Facility

Our Machines & Capabilities

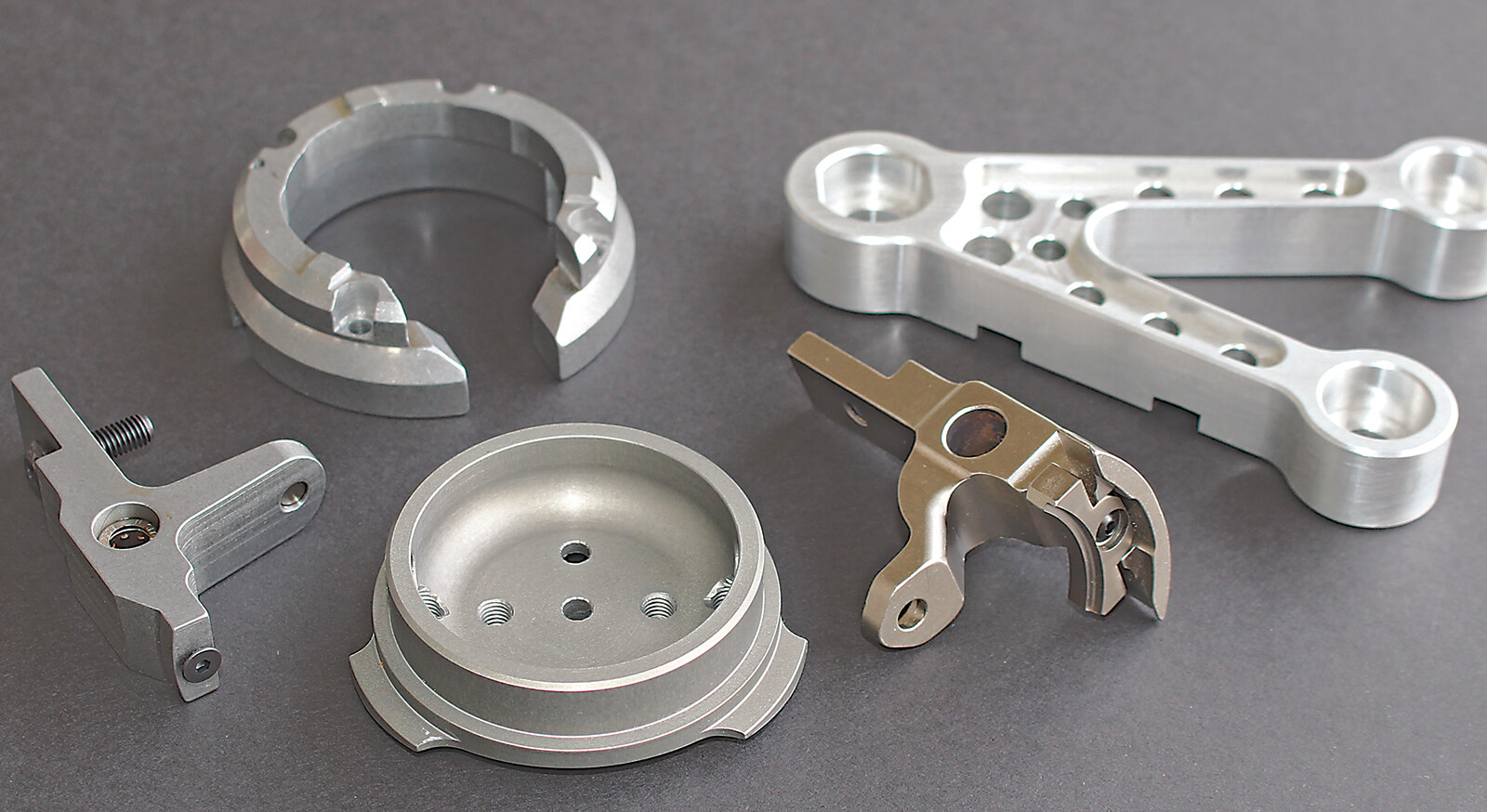

Machining Technologies, LLC is an ISO 9001:2015 certified company producing high quality machined products at competitive pricing.

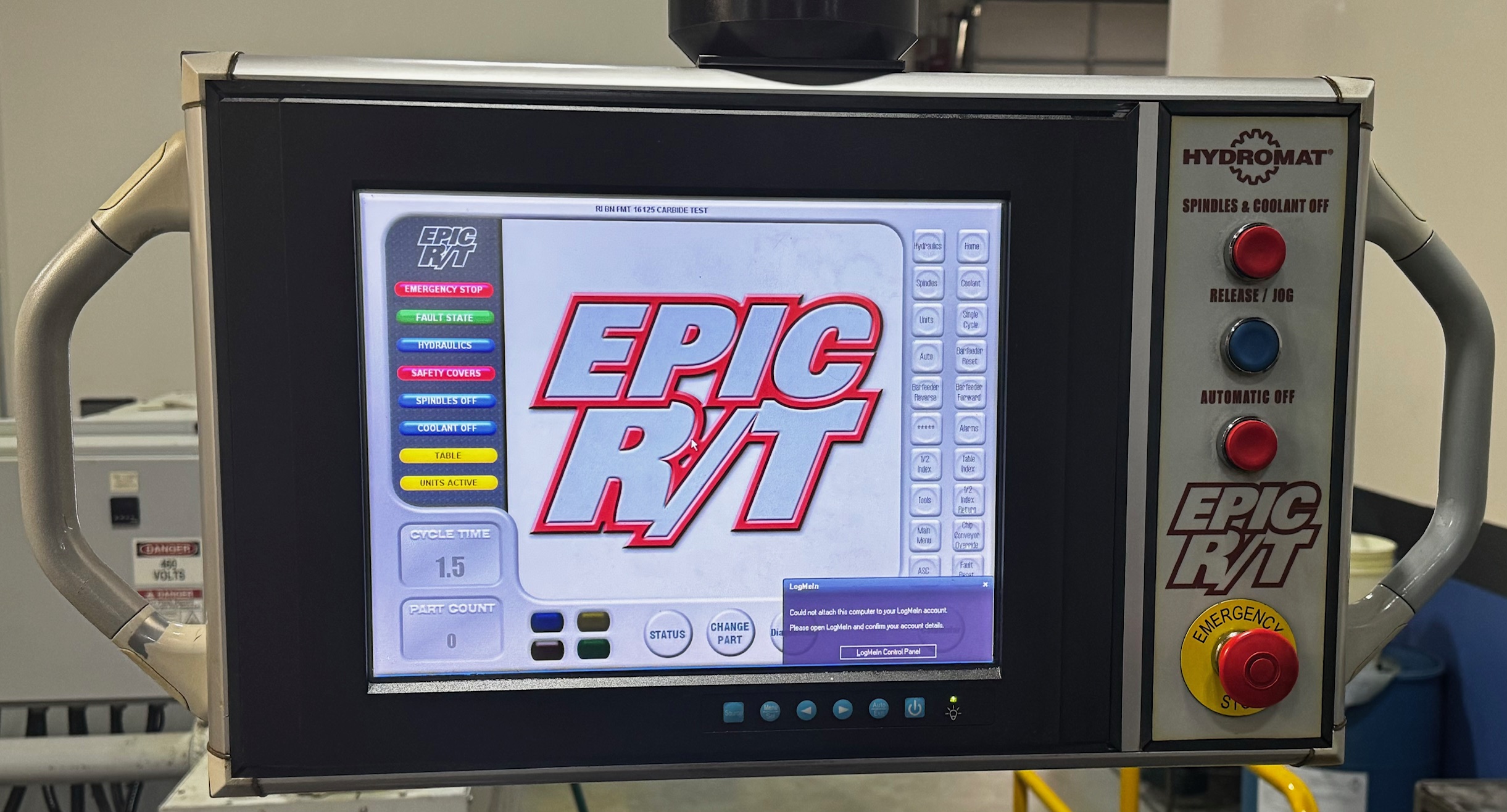

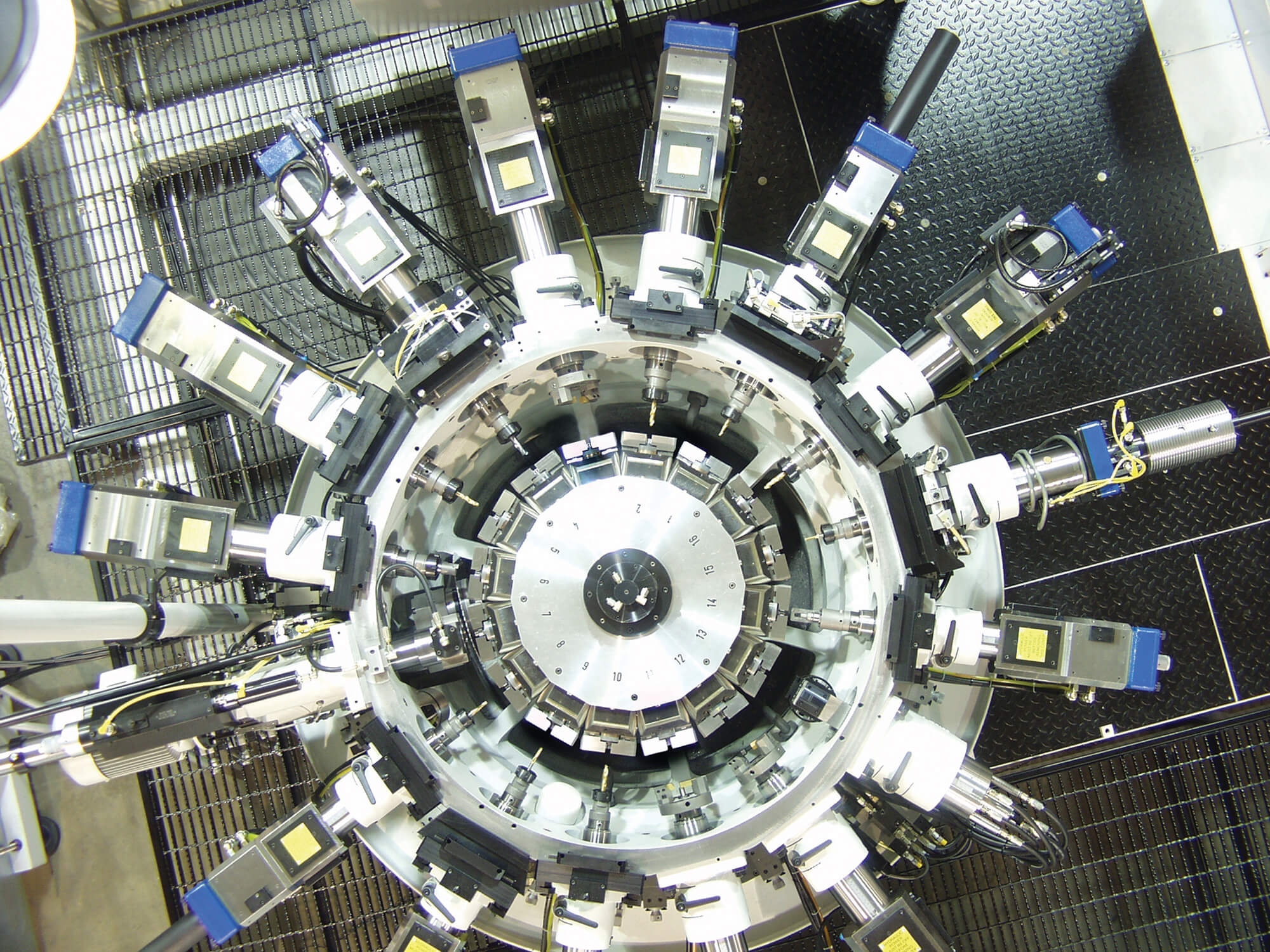

Hydromat Shop (22 machines total)

- High volume machining

- Our machines range from 10 – 16 stations and can accommodate up to 45 MM without modification.

- TWELVE Hydromat HW 25-12’s with 25 MM Capacity

- FIVE Hydromat Pro 20 ( Upgraded to 25 MM Capacity)

- TWO 45 MM 12 Station Hydromat Epic RT CNC’s

- ONE 45 MM 12 Station Hydromat “Legacy” with Bundle Loader

- TWO 32/45 16 Station Hydromat Epic with Bar loaders

- Flexible Feeding systems including Magazine loading of blanks or forgings, 12-16 foot Bar Loaders, Robot Loading, and Coil Feeders.

- Spare units available for new set-ups including standard hydraulic units, 2 axis CNC profiling units, 3 axis Milling Units and single axis up to 40,000 RPM are in-house to minimize downtime and aid in speeding up new parts for customers.

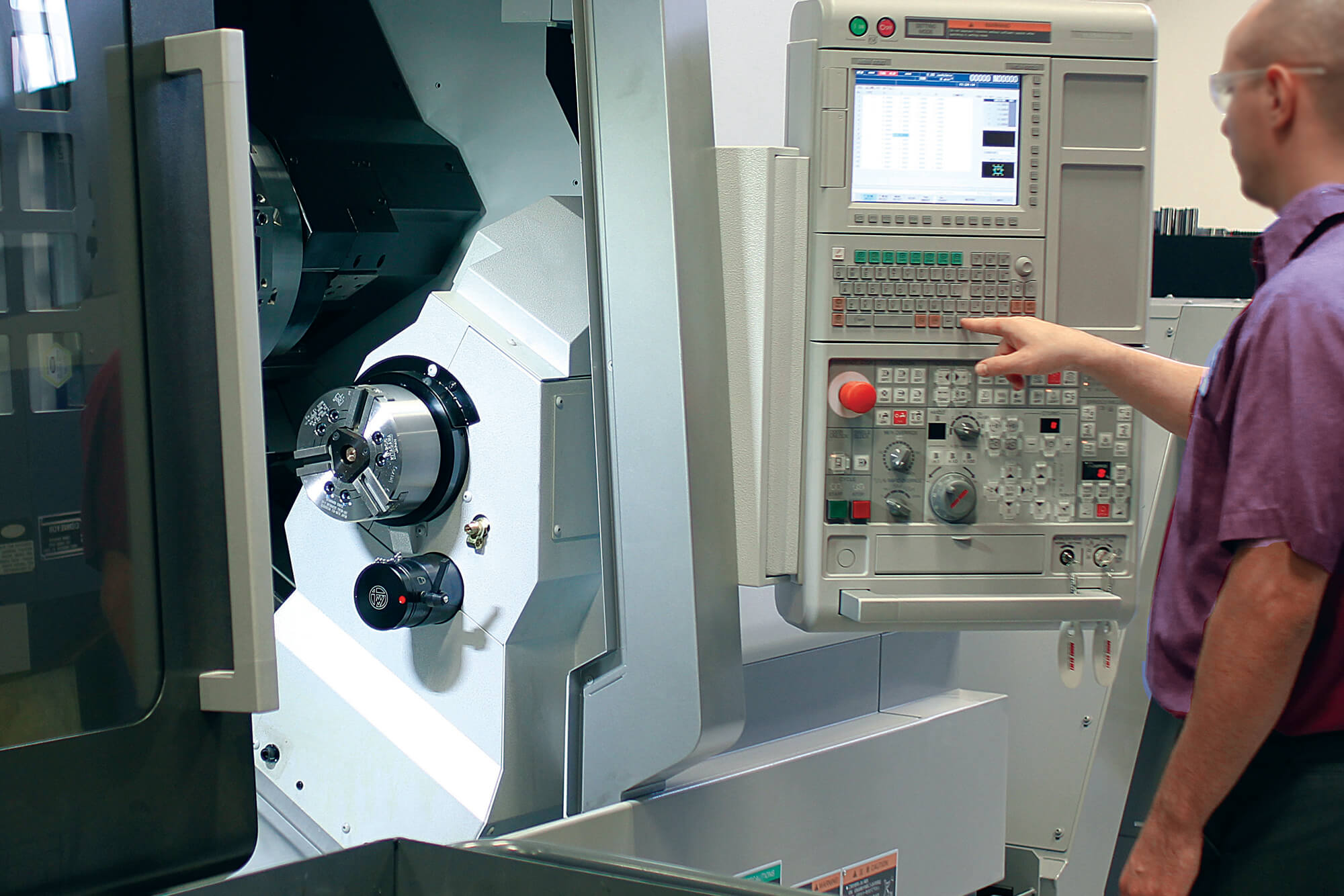

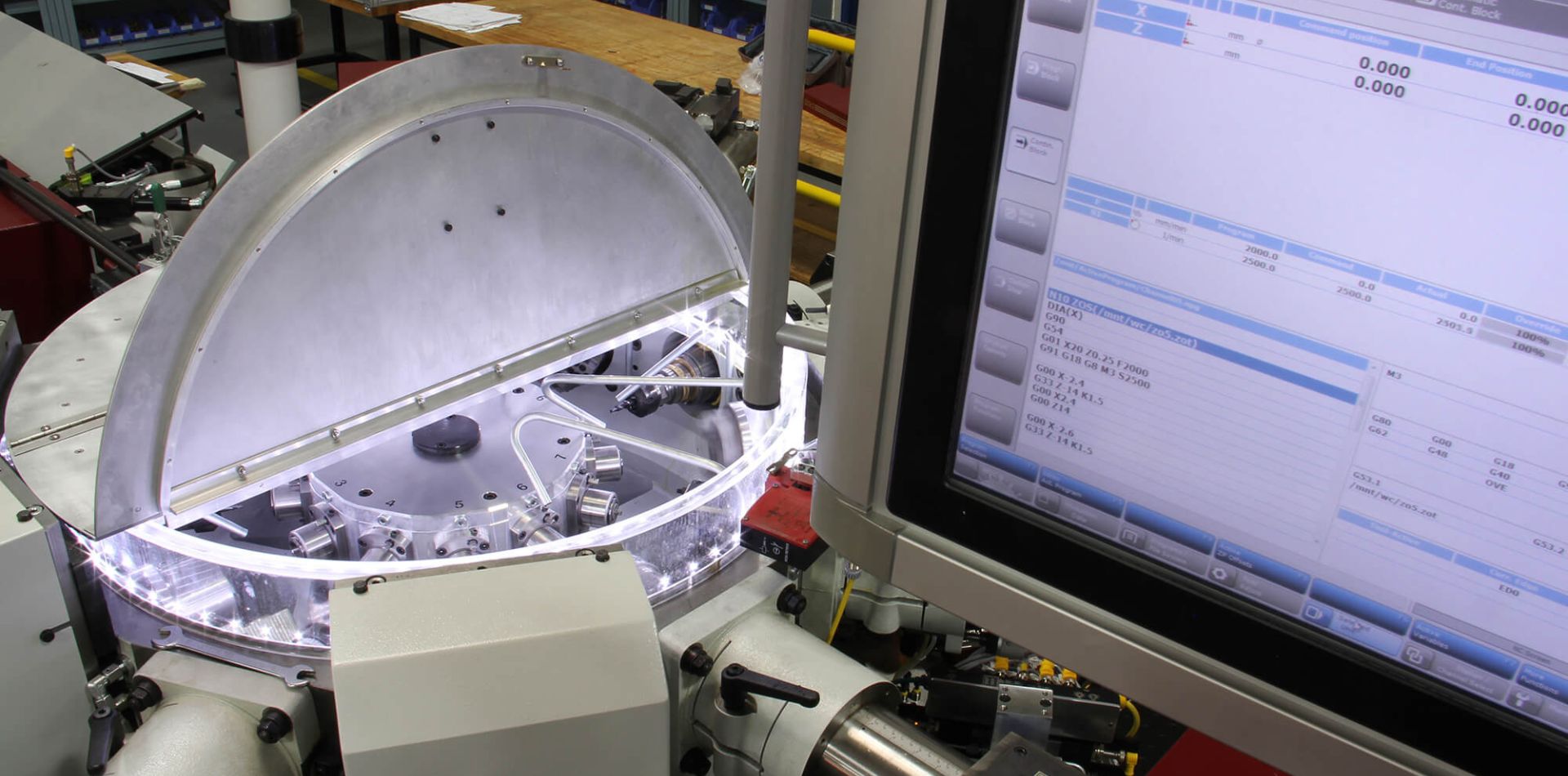

CNC Shop and R&D

- Prototypes to medium-high volume machining

- 3 Proto Trak 1845 SX lathes

- 3 Proto Trak Milling machines 2 DPM3’s and One DPM5

- FANUC iMED Wire EDM

- 6 Mori Seiki NLX 2500 SY Twin spindle lathes with Bar Loaders

- 3 Mori Seiki SL Series Chuck type lathes-one with a Bar Loader

- 2 Mori Seiki DuraMill 5100 10k RPM spindle, 30 tool changer

- ROFIN CNC 120 Joule 4 axis CNC Laser welder

- Hoffman Balancing machine

- MasterCam CAD CAM software

- Solid Works 8 SEATS

Escomatic Shop

- High Volume Small Diameter machined Parts

- 2 ESCOMATIC D6 Wire fed Screw Machines; Maximum Capacity .270 Diameter by 20” long

- 1 ESCOMATIC D2 Wire fed Screw Machine Capacity .012” to .118”

Inspection | ISO9001:2015 Certified

- Starrett AVR 300 Hybrid Vision/CMM System

- Magellan V-300 Digital Comparator

- Deltronic DH-14 Optical Comparator

- B&S Heightmaster

- 4 Tesa Electronic Height gages

- TRIMOS Electronic Height Gage

- 4 Mitutoyo Tool Room microscopes

- Bench centers, and all other related inspection equipment.

Support Equipment

- Two Hardinge manual lathes

- 2 Bridgeports

- 2 Harig surface Grinders 6” x 12”

- Carbide grinders

- Mig and Tig welders

- Plasma Cutter

- 5 OTEC Disc Finishers

- FANUC ArcMate 50iB Robot

- DAREX XPS16 CNC drill sharpener

Engineering & Assembly

- 8 person team of engineers, and a full assembly department. Making MTL a true “One Stop Shop”! From concept to reality – Prototype to 10 million pieces, we have the solutions!

Ready to Transform Your Manufacturing Process?

Don’t let outdated manufacturing methods hold your business back. Embrace the future of precision engineering with Machining Technologies.

Step into the future of manufacturing with our cutting-edge machines. Our team of skilled professionals harnesses the power of these technological marvels to bring your designs to life with unparalleled accuracy and speed.

CONTACT US